EVOLUTION OF SURFACES UNDER SERVICE LOAD

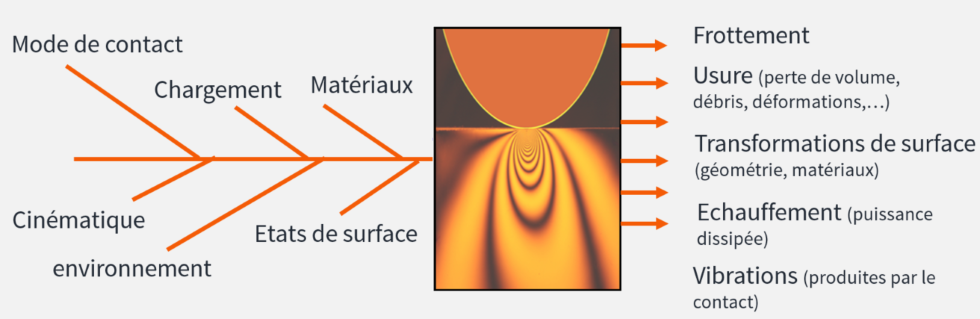

The surface roughnesse play a considerable role in the performance of functional interfaces subject to service loads. The control of surface roughness has an impact on various functionalities such as steering, power transmission, sealing, fastenings, etc. In addition, they are involved in a large number of energy dissipation and/or damage phenomena such as friction, wear, overheating, vibrations caused by friction, scaling, etc.

It is necessary to distinguish early changes to surfaces stemming from running-in and which are aimed at improving performance from evolutions in service which progressively degrade performance and reduce lifetime. In the tribology and materials topic, we approach this problem in several ways :

- by functional analysis,

- by modelling surface roughness,

- by tribological tests,

- by measuring evolutions of microgeometry,

- by simulating phenomena.

Functional analysis allows identifying the phenomena to be optimised and identifying the influential parameters of the first order (including surface roughness, the materials, the type of contact, the relative kinematics and load). It allows orienting the design approach and determining the correct experimental characterisation strategy.

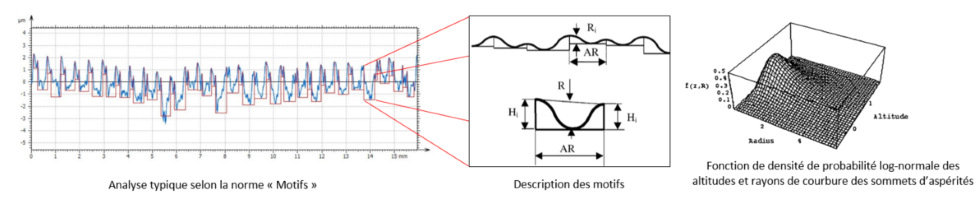

Modelling surface roughness is aimed at obtaining a description of the microgeometry in relation with the desired functionality. It relies as much as possible on normalised parameters and on stochastic descriptions of functional surfaces. This approach permits obtaining the average response of a class of surfaces to a load.

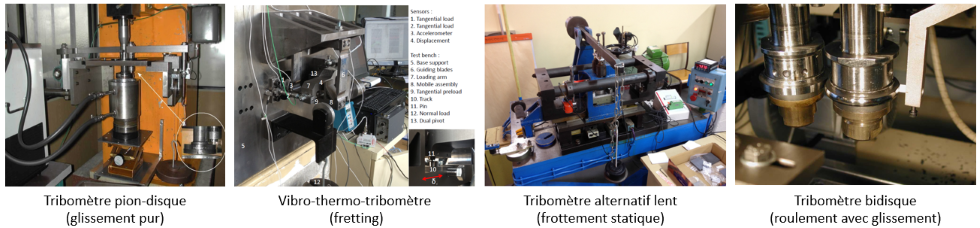

Tribological tests are essential to understand the phenomena involved, their control and to determine the domains of validity of the models proposed. To achieve this, the tribology and materials team has for a long time designed and developed for itself and for its partners, original test benches that allow realistically subjecting test specimen representative of industrial applications to loading. This approach is facilitated by the availability of easily adaptable test benches.

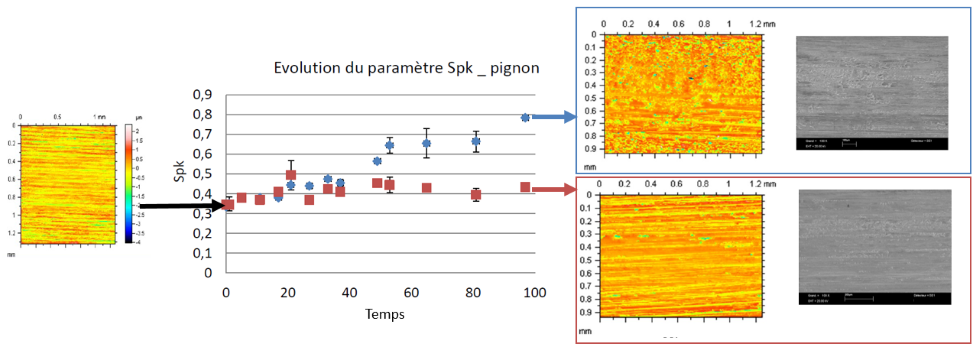

Measuring microgeometric evolutions is a key step of this activity as it permits describing and quantifying the effects of load on the microgeometry of parts in contact. Several techniques are used : optical microscopy, SEM, surfometers with and without contact, etc. This quantification, coupled with test results, is used to estimate the performances of the different solutions tested (materials, surface treatments, coatings, etc.).

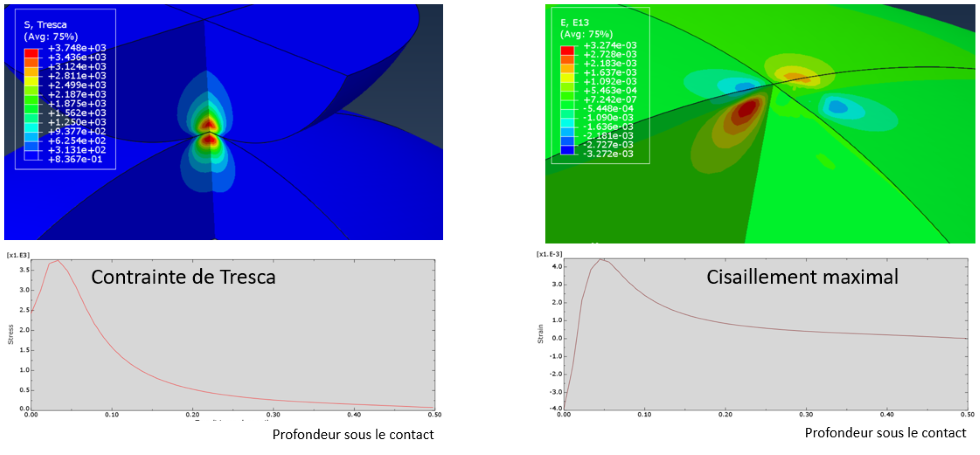

Simulating phenomena makes it possible to understand the physics involved by “observing” the interface when it is closed (when the contact is established), where it is impossible to use test instruments. This approach takes into account the nonlinear behaviour of materials and helps the choice of suitable surface coatings. In particular, simulation makes use of the finite elements method.

Collaborations:

GDR SurfTopo, ARTEMA, Total, Safran Aircraft Engines, Valeo

References:

[1] Ich Tach Tran, Vérification de la validité du concept de surface somme par une approche statistique du contact élastique entre deux surfaces rugueuses, thèse soutenue le 26/01/2015, Ecole Doctorale SPI, Ecole Centrale de Paris.

[2] Stéphane Tchoundjeu-Ngatchou, Caractérisation des performances d’endurance des lubrifiants par suivi des états de surfaces tridimensionnels, thèse soutenue le 08/10/2013, Ecole Doctorale SPI, Ecole Centrale de Paris.

[3] F. Robbe-Valloire, B. Paffoni, R. Progri, Load transmission by elastic, elasto-plastic or fully plastic deformation of rough interface asperities, Mechanics of Materials 33 (2001), Issue 11, pp.617-633

[4] F. Robbe-Valloire, Statistical analysis of asperities on a rough surface, Wear 249 (2001) 401–408

[5] M. Quillien, F. Robbe-Valloire, et al., Guide de préconisations pour augmenter et mesurer les performances tribologiques, ARTEMA , 2017. https://www.artema-france.org/wp-content/uploads/2017/07/Guide_de_preconisations_performances_tribologiques_Artema_supmeca_2017.pdf

[6] ISAE-Supméca (TriboMat) ARTEMA Guide méthodologique pour la définition, la réalisation et le contrôle des portées de joints d’étanchéité à paraître.