ENERGY DAMPING AND DISSIPATION IN ASSEMBLIES

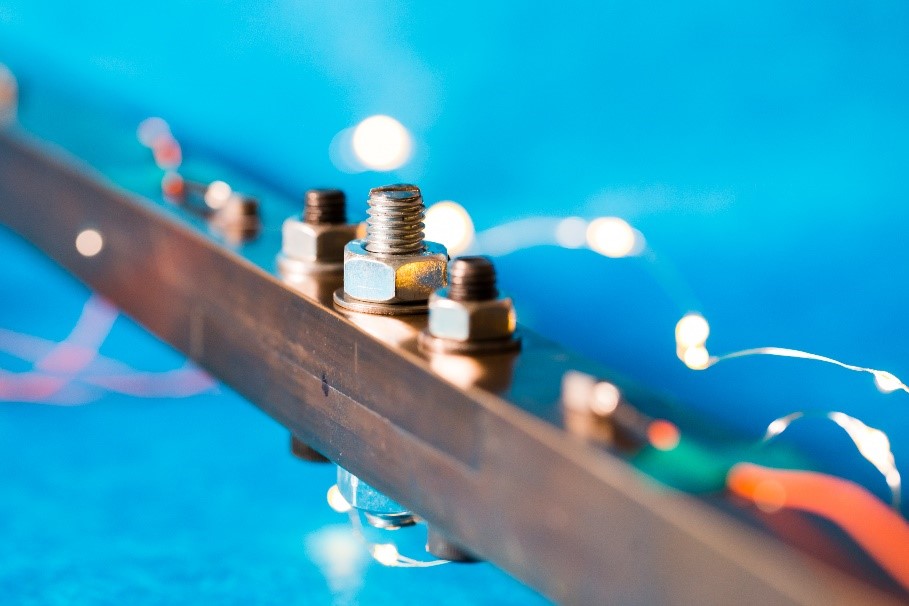

During the design phase of a structures, predicting their dynamic behaviour is often degraded by errors due to the poor evaluation of their global damping. The level of the vibration is heavily dependent on the damping caused by the assemblies of substructures with each other. This damping is consecutive to a loss of energy by friction due to partial sliding in the linking interfaces. The purpose of these works is to focus on this energy dissipated by friction occurring during the vibrations of the structure and influencing its dynamic behaviour.

The works performed are aimed at :

- quantifying this damping experimentally,

- evaluating this damping at different scales (microgeometric contact, link, structure) numerically.

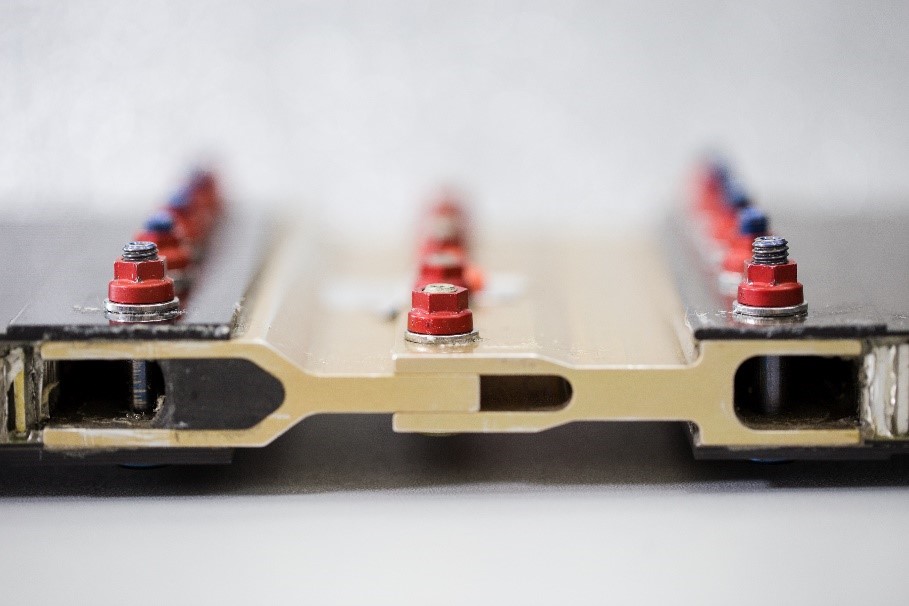

Moreover, recent works are aimed at designing and prototyping damping link technologies for metal assemblies. The justification of these works is based on the fact that modern structures must combine reliability, lifetime, comfort, lightness, low-cost, rapidity and reduced energy consumption. Taken separately, although of different natures, these parameters are all improved when damping in the structure is increased. The reduction of vibrations always results from a compromise between these different parameters and the addition of damping cannot improve them all at once. These works are aimed at maximising the contribution of damping in mechanical links and more generally to improving the performance of structures.

The research carried out is supported by institutes and industrial companies in the framework of research programmes (R&T CNES, FUI (MAIAS, CLIMA), IRT SystemX, EDF, ASTECH, JPB SYSTEM, AIRBUS, SOPEMEA, AVNIR, SDTOOLS, FCBA.